Nitric acid (HNO3) is one of the most widely used digestion reagents and the most widely used primary oxidant for the decomposition of organic matter.

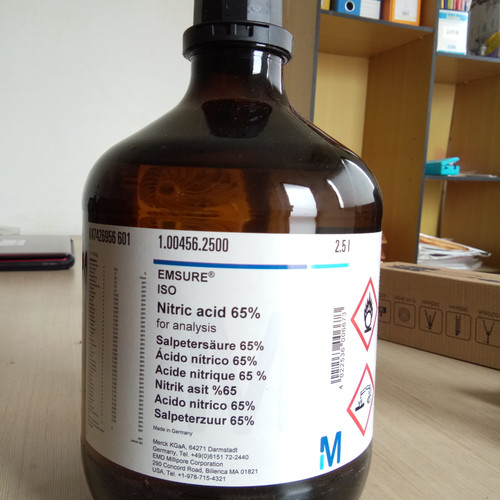

Nitric acid (HNO3, also known as aqua fortis and spirit of niter) is a highly corrosive mineral acid. The pure compound is colorless, but older samples tend to acquire a yellow cast due to decomposition into nitrogen oxides (NOx) and water. Most commercially available nitric acid has a concentration of 68% (v/v) in water. When the solution contains more than 86% (v/v) nitric acid, it is referred to as fuming nitric acid, which, depending on the amount of nitrogen dioxide (NO2) present, is further characterized as (i) white fuming nitric acid or (2) red fuming nitric acid at concentrations above 95%. Nitric acid is the primary reagent used for nitration—the addition of a nitro group ( NO2), typically to an organic molecule. While some of the resulting nitro compounds are shock-sensitive and thermally sensitive explosives (such as nitroglycerin and trinitrotoluene (TNT)), some are sufficiently stable to be used in munitions and demolition, while others are still more stable and used as pigments in inks and dyes. Nitric acid is also commonly used as a strong oxidizing agent.

NO2), typically to an organic molecule. While some of the resulting nitro compounds are shock-sensitive and thermally sensitive explosives (such as nitroglycerin and trinitrotoluene (TNT)), some are sufficiently stable to be used in munitions and demolition, while others are still more stable and used as pigments in inks and dyes. Nitric acid is also commonly used as a strong oxidizing agent.

Nitric acid is used as an intermediate in the manufacture of ammonium nitrate (NH4NO3), which is primarily used in to manufacture fertilizers. Another use for nitric acid is in the oxidation process for the manufacture of adipic acid (HO2CCH2CH2CH2CH2CO2H) that is a dicarboxylic acid used in the production of nylon.

Nitric acid is also used in organic oxidation to manufacture terephthalic acid (C6H4(CO2H)2) and other organic compounds.

Nitric acid is also used in the manufacture of explosives, such as nitrobenzene derivatives, dinitrotoluene derivative, and TNT derivatives, and for producing other chemical intermediates.

Nitric acid is produced by two methods: (1) The first method utilizes oxidation, condensation, and absorption to produce a weak nitric acid that can have concentrations ranging from 30% to 70% (v/v) nitric acid, and (2) the second method combines dehydrating, bleaching, condensing, and absorption to produce high-strength nitric acid from weak nitric acid; high-strength nitric acid generally contains more than 90% (v/v) nitric acid.

The process typically consists of three steps: (1) ammonia oxidation, (2) nitric oxide oxidation, and (3) absorption. Each step corresponds to a distinct chemical reaction. For the ammonia oxidation step, a 1:9 ammonia/air mixture is oxidized at a temperature of 750–800°C (1380–1470°F) as it passes through a catalytic converter:

The most commonly used catalyst is composed of platinum (90%, w/w) and rhodium (10%, w/w) gauze, and under these conditions. the oxidation of ammonia to nitric oxide proceeds in an exothermic reaction with a yield range on the order of 93%–98% (v/v). Higher catalyst temperatures increase reaction selectivity toward the production of nitric oxide (NO), while lower catalyst temperatures tend to be more selective toward the production of nitrogen (N2) and nitrous oxide (N2O). Nitric oxide is considered to be a criteria pollutant, and nitrous oxide is known to be a greenhouse gas. The nitrogen dioxide/dimer mixture then passes through a waste heat boiler and a platinum filter.

The nitric oxide formed during the ammonia oxidation is oxidized in another separate step. In this step, the process stream is passed through a cooler/condenser and cooled to 38°C (100°F) or less at pressures up to 116 psi, and the nitric oxide reacts noncatalytically with residual oxygen to form nitrogen dioxide and the liquid dimer, nitrogen tetroxide; this slow, homogeneous reaction is temperature and pressure dependent:

At low temperatures and high pressure, the maximum production of nitrogen dioxide occurs within a minimum reaction time.

Absorption is the final step in the process, and the nitrogen dioxide/dimer mixture is introduced into an absorption process after being cooled. The mixture is pumped into the bottom of the absorption tower, while liquid dinitrogen tetroxide is added at a higher point. Deionized water enters the top of the column, and both liquids flow in a countercurrent direction, thereby allowing the exothermic oxidation reaction to occur in the free space between the trays, while absorption occurs on the trays. The absorption trays are usually sieve or bubble cap trays:

A secondary air stream is introduced into the column to reoxidize the nitric oxide, which is formed in this reaction. This secondary air stream also removes any nitrogen dioxide from the product acid. An aqueous solution of (typically) 55%–65% (v/v) nitric acid is withdrawn from the bottom of the tower; the acid concentration can vary from 30% to 70% (v/v) nitric acid. However, the acid concentration depends upon the temperature, pressure, and number of absorption stages as well as on the concentration of nitrogen oxides entering the absorber.

While configurations may differ somewhat between plants, three essential steps are commonly employed. In the first step, ammonia is oxidized to nitric oxide (NO) in a catalytic convertor over a platinum catalyst (90% platinum and 10% rhodium gauze). The reaction is exothermic (heat releasing) and produces nitric oxide in yields on the order of 93%–98%. The reaction proceeds at high temperatures ranging from 750°C to 900°C (1380–1650°F). The resulting mixture from this reaction is then sent to a waste heat boiler where steam is produced. In the second step, nitric oxide is oxidized by passage through a cooler/condenser, where it is cooled to temperatures on the order of 38°C (100°F) or less, at pressures of up to 116 psia. During this stage, the nitric oxide reacts with residual oxygen to form nitrogen dioxide and nitrogen tetroxide. The final step introduces this mixture of nitrogen oxides into an absorption process where the mixture flows countercurrent to deionized water and additional liquid dinitrogen tetroxide. The tower is packed with sieve or bubble cap distillation type trays. Oxidation takes places in between the trays in the tower; absorption occurs on the trays. An exothermic reaction between NO2 and water occurs in the tower to produce nitric acid and NO. Air is introduced into the tower to reoxidize the NO that is being formed and to remove NO2 from the nitric acid. A weak acid solution (of 55%–65 %) is withdrawn from the bottom of the absorption tower.

High strength nitric acid (98%–99%, v/v) can be obtained by concentrating weak nitric acid (30%–70% concentration) using extractive distillation. The weak nitric acid cannot be concentrated by simple fractional distillation. The distillation must be carried out in the presence of a dehydrating agent. Concentrated sulfuric acid (typically 60%, v/v sulfuric acid) is most commonly used for this purpose. The nitric acid concentration process consists of feeding strong sulfuric acid and 55%–65% (v/v) nitric acid into the top of a packed dehydrating column at approximately atmospheric pressure. The acid mixture flows downward and concentrated nitric acid leaves the top of the column as 99% (v/v) vapor that contains a small amount of nitrogen dioxide and oxygen that result from dissociation of nitric acid. The concentrated acid vapor leaves the column and goes to a bleacher and a countercurrent condenser system to achieve the condensation of strong nitric acid and the separation of oxygen and nitrogen oxide by-products. These by-products then flow to an absorption column where the nitric oxide mixes with auxiliary air to form nitrogen dioxide, which is recovered as weak nitric acid. Inert and unreacted gases are vented to the atmosphere from the top of the absorption column.

Emissions from the manufacture of nitric acid include mostly nitrogen oxides (NO and NO2), and trace amounts of ammonia and nitric acid mist. The tail gas from the acid absorption tower is the largest source of nitrogen oxide emissions. These emissions can increase when insufficient air is supplied to the oxidizer and absorber, under low absorber pressure conditions, and during high-temperature conditions in the cooler/condenser and absorber. Other factors may contribute, such as high throughputs, very high-strength products, or faulty compressors or pumps.

Control of emissions from nitric acid plants is usually accomplished through either extended absorption or catalytic reduction. Extended absorption works by increasing the efficiency of the absorption process. Catalytic reduction oxidizes nitrogen oxides in the tail gas and reduces them to nitrogen. While catalytic reduction is more energy-intensive, it achieves greater emission reductions than the extended absorption method. Less used control options include wet scrubbers or molecular sieves, both of which have higher capital and operating costs than the other options.

Solid wastes from nitric acid manufacture include spent catalysts that are either returned to the manufacturer or disposed of. Dust from the catalyst may settle out in the equipment, but if it contains precious metals, it is recovered and sent for reprocessing to an outside vendor. Precious metals (e.g., platinum) lost from the ammonia oxidation catalyst are captured by a recovery gauze (getter), which must be replaced periodically and is reprocessed by a gauze manufacturer. Filters used for ammonia/air filtration must also be replaced.